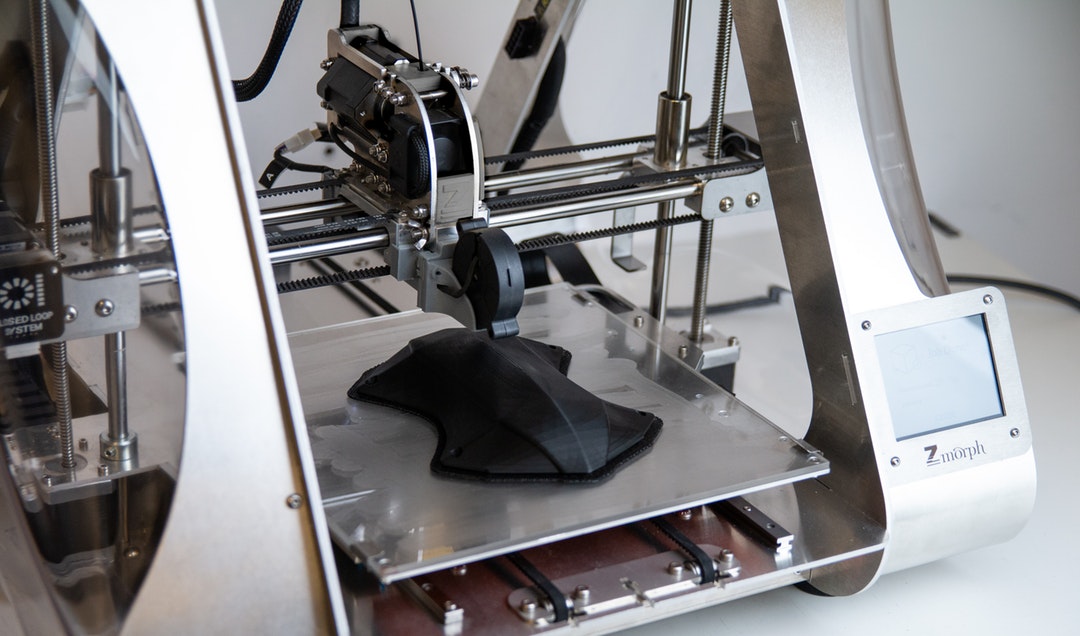

3D printing has already revolutionized the healthcare industry. For example, 3D printers have recreated complex body parts like blood vessels.

The benefits of 3D printing are almost endless. Read on to learn some 3D printing advantages, especially in the field of medicine.

More Affordable Prototyping

Traditional prototyping injection mold tools are expensive. 3D printers offer more affordable options to create parts and tools. By using additive manufacturing, the rates are much cheaper than traditional machining.

In fact, it’s become so affordable that anyone can add a 3D printer to their makerspace products.

Benefits of 3D Printing in the Medical Field

The pros of 3D printing in the medical field are the ability to produce cheaper surgical tools.

It costs less to produce forceps, clamps, and hemostats than buying stainless-steel equivalents. Many 3D-printed solutions come with a favorable price tag.

3D printing prosthetics are also low-cost compared to traditional ones. Prostheses are subject to wear and tear. Producing and replacing them can cost up to $10,000.

Young children sometimes outgrow their prosthetic limbs within months. With 3D printing, customizing a prosthetic is easier and more affordable. Replacements cost hundreds of dollars rather than thousands.

Quick Production

Traditional prototyping often takes weeks. It’s also an extended process. You examine your prototype, change it, and reproduce. Then the process begins again.

With 3D printing, producing a prototype takes hours rather than days. The design converts to a readable file, and the printer prints it. Redesigning prototypes follows the same quick process.

Customize with Ease

With 3D printing, you can customize by modifying the prototype design. For this reason, medical and dental manufacturers customized 3D prints. There is little added cost to customizing prototype files.

Further, changing shapes and sizes is easy to do with a 3D printer. The printer’s nozzle can build countless shapes and figures. The result is higher structural integrity. 3D printing produced implants for skulls, bones, and aerodynamic parts.

Diverse Materials

Mixed raw materials aren’t ideal for mass-production due to cost. Combining the physical and chemical properties is difficult.

3D printing fares better in this area. Because it uses plastic, 3D printing is compatible with glass, metals, and ceramics.

It’s also compatible with silver, gold, and paper. What’s impressive is that it’s also compatible with biomaterials and some food materials.

Environmentally Friendly

3D printing is energy-efficient and produces less waste compared to other production methods. It’s sustainable due to additive manufacturing. The final 3D-printed object is about 60 percent lighter, though it is sturdy.

In short, it uses less energy and reduces waste to a minimum.

Keeping Up with Technology

No matter the industry, professionals within it must keep up with technology. For many industries, 3D printing has amazing potential. This article has focused 3D printing in healthcare.

The main benefits of 3D printing are that you can produce products cheaper and faster. Please visit our Business Advice section for more articles on how technology can help your industry.